Inerting is a process in which an explosive or reactive atmosphere is replaced by an inert gas, usually nitrogen, in order to maintain the safety and quality of equipment.

The purpose of inertisation is mainly to avoid dangerous reactions, such as oxidation or the release of toxic gas.

The inertisation process can be applied using different materials and substances, such as gases, liquids or solids, and can be carried out in different ways, depending on the material and the objective to be achieved.

For example, inerting industrial equipment may involve filling it with an inert gas, such as nitrogen, to prevent oxidation of the contents.

The main advantages of inertisation are the following:

1. Avoidance of unwanted chemical reactions: Inertisation avoids dangerous chemical reactions or reactions that may affect the quality or performance of equipment or products.

2. Protect equipment: In most cases, Inerts help to protect chemical industry equipment and facilities from degradation or damage caused by such unwanted reactions.

3. Safety: Inerting also contributes to improving plant safety, as it prevents the release of toxic or flammable gases that can be dangerous for both people and the environment.

4. Efficiency: By inertising the equipment we also increase production efficiency by avoiding product losses or reduced yields caused by possible chemical reactions.

5. Facilitates storage and transport: Inerting facilitates the transport and storage of chemical products, preventing them from degrading or reacting with the container or the environment during the logistics process.

How is the inertisation process carried out?

The substances or materials we use at Lagupres vary depending on the equipment to be protected. Some of the most common examples are:

- Inert gases: This is the most common form of inerting. By injecting inert gases such as nitrogen, carbon dioxide or argon, which do not react with other materials or substances, we help to protect the contents of equipment or prevent the oxidation of some products.

- Chemical agents: We can use chemical agents such as corrosion inhibitors or antioxidants, protecting equipment or materials from oxidation or degradation.

At Lagupres, we have professionals with the specific knowledge to carry out the process, as well as the best equipment and materials.

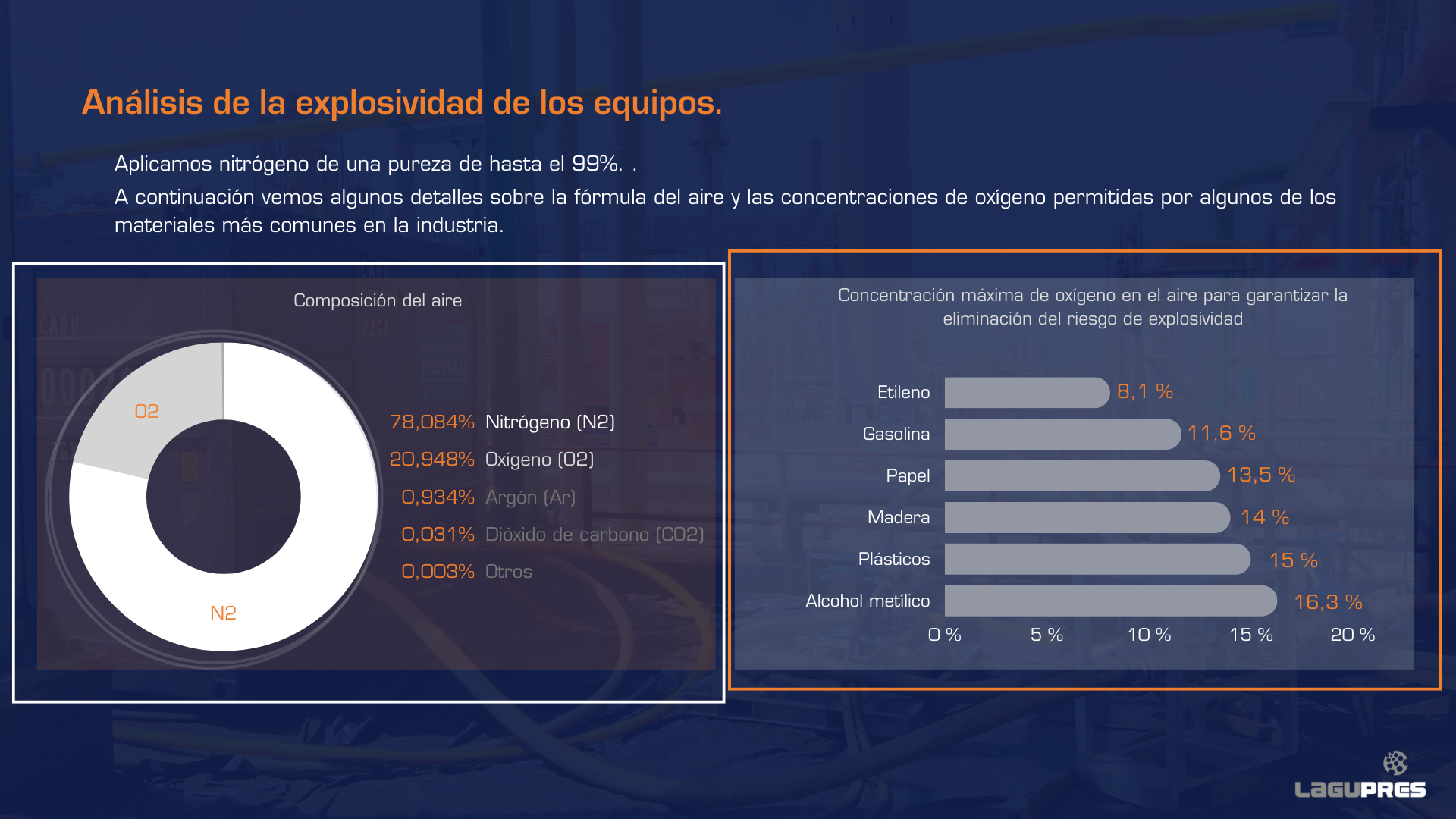

Before each intertisation work, we study the explosiveness of the equipment to be treated and the amount of oxygen in the air allowed for each gas to avoid possible explosions.

How long does the effect of inertisation last?

The duration of an inertisation process is not objective and depends on several factors, including the equipment or the material or substance being protected, the method used to inert, the environmental conditions and the use of the product or equipment. The inerting process is ideal in a variety of industries, including petrochemical, pharmaceutical and food industries, among others.

Don’t forget to follow us on LinkedIn! Don’t miss our work, infographics, news, etc.!