The evolution of technology has enabled robotisation of various industrial tasks, and robotised tank cleaning is no exception.

In the industrial cleaning industry, the adoption of robots to perform cleaning tasks in complex environments has revolutionised the landscape.

In this post, we will explore the advantages of reservoirs and tank robotised cleaning, the hazards that are avoided and other highlights of this innovative solution.

How does the Reservoirs and Tank Cleaning Robot work?

Storage tanks are subject to extensive maintenance and control measures. They must be emptied and cleaned from time to time. In the cleaning process, aqueous by-products are generated and must be recycled to recover the original product.

Dirt and product residues are automatically removed from the tank and then separated into the different phases by a decanter and transferred to a recycling process.

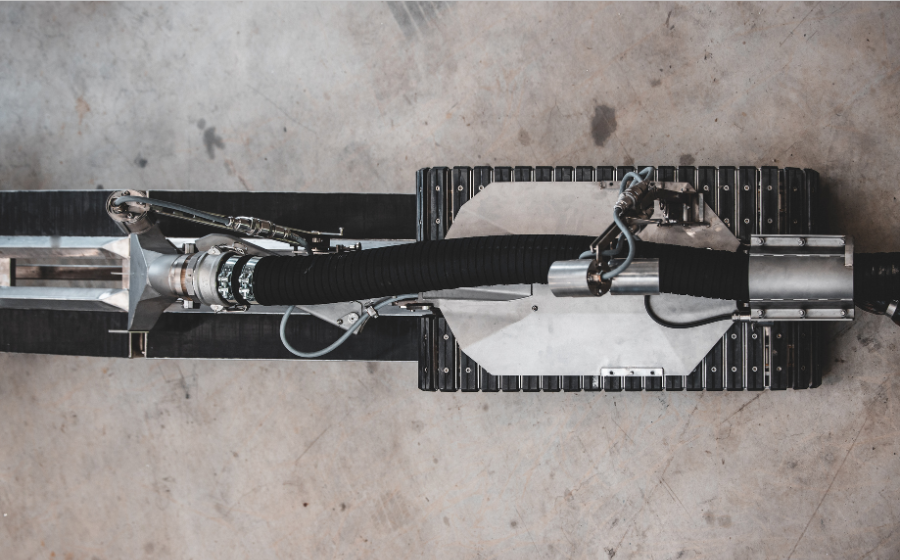

Now, together with LOBBE, we use a combination of their own tank cleaning robot, which removes solid waste and sludge from the tank, and a complex modular settling system.

The oil residues recovered in this process can be fed back into the production process and reused.

Tank cleaning robot features

The robotised tank cleaning robot is capable of vacuuming various waste products such as liquids, sludge, grease, oils, fuels and other chemicals. The robot is applicable to Atex 0 areas.

Optimised Efficiency and Productivity:

Robotisation of tank and tank cleaning offers a significant improvement in efficiency and productivity.

Faster robotised tank cleaning

The robot is designed to access confined spaces and work in harsh environments, allowing cleaning to be carried out quickly and accurately.

Continuous robotic operation

These robots can operate 24 hours a day, 7 days a week, ensuring constant cleaning and reducing downtime of tanks and reservoirs.

Greater Security for Workers:

Manual cleaning of tanks and reservoirs can be extremely dangerous for workers.

Elimination of occupational hazards

By using the robot, the risks of direct exposure of workers to confined spaces and chemicals are eliminated.

Remote operation from a safe location

Our colleagues can control the robots remotely from a safe location, thus minimising occupational hazards and protecting the physical integrity of the workers.

The robot control room is ATEX 1 certified.

Improving the Quality of Robotised Tank Cleaning:

Robotised tank cleaning ensures more accurate and thorough cleaning compared to traditional methods.

Advanced debris detection and removal technology

The robots are equipped with sensors and cameras that enable them to detect and remove debris effectively.

Pollutant prevention

This avoids the presence of residues or contaminants that could adversely affect products or materials stored in tanks and reservoirs.

Conclusions on Robotised tank cleaning

Robotised tank cleaning is an innovative and efficient solution in the industrial cleaning industry. Optimised efficiency, improved worker safety, cleaning quality and regulatory compliance are just some of the benefits offered by this technology. By adopting Robotised tank cleaning, companies in various sectors can improve their competitiveness and ensure a safer and more efficient working environment.

If you are interested in taking advantage of the benefits of reservoirs and Tanks robotised cleaning, please do not hesitate to contact us. We are committed to excellence and innovation in industrial cleaning.